WiseBond® Bar & Table Top Epoxy is a DIY friendly countertop, bar, and wood slab epoxy top coat. Poured over wood (river tables) or concrete surfaces, it provides a super wet gloss, and is a self-leveling clear (or tinted) epoxy that is UV stable. Our simple 1:1 ratio epoxy kit easily mixes and pours, producing a superior epoxy project with the market's highest clarity, gloss, shine, and durability.

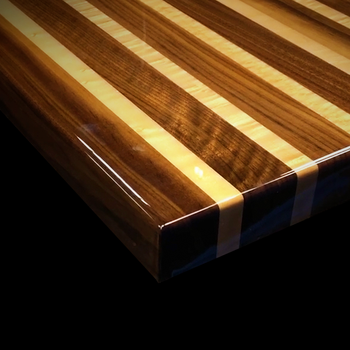

Our table and countertop epoxy is a thin pour epoxy that produces a rich super gloss (glass-like) look when poured clear. Typically used for a 1/8 in. thick clear finish coat for bar tops, tables, river tables and most any table, bar, or countertop surface. It delivers an epoxy flood coat ideal for applications requiring a high level of see through transparency. It can also be tinted with mica powders, dyes and alcohol pigments for stunning faux table top finishes, or kitchen and bath remodels.

Our table and countertop epoxy is a thin pour epoxy that produces a rich super gloss (glass-like) look when poured clear. Typically used for a 1/8 in. thick clear finish coat for bar tops, tables, river tables and most any table, bar, or countertop surface. It delivers an epoxy flood coat ideal for applications requiring a high level of see through transparency. It can also be tinted with mica powders, dyes and alcohol pigments for stunning faux table top finishes, or kitchen and bath remodels.

Our table top epoxy can be colored/tinted with WiseColor™ mica powder, alcohol inks, opaque resin pigments, or our color shift/glow-in-the-dark/fluorescent resin tints!

WiseBond® Bar & Table Top Epoxy features an easy 1:1 mix ratio and a 24 hour cure, giving you plenty of time to perfect your epoxy table or countertop project. This table top epoxy is LOW odor and can be mixed and poured indoors.

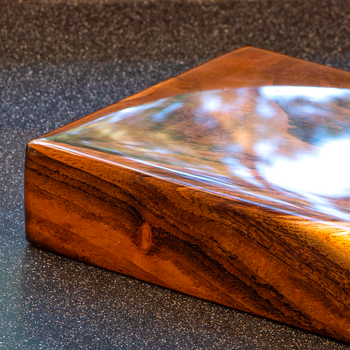

WiseBond® Bar & Table Top epoxy poured over wood slabs, bars and tables, preserves the wood, brings out the natural wood luster, and highlights the natural wood grains. America's choice for self-leveling, water and chemical resistance, the highest super gloss finish on the market!

Each table top epoxy kit includes a resin (Part A) and a hardener (Part B). The 1 Gallon Kit includes 1/2 gallon of resin and 1/2 gallon of hardener. Mix equal parts of A and B together. Mix thoroughly for three (3) minutes and apply to the surface between 77°F- 85°F. Allow 24 hours between pouring additional layers. Wait 3 days for a full cure and 30 days for a full hard cure.

FOOD SAFETY: Products "WiseBond® Deep Pour 2” Epoxy: Part A and B, and WiseBond® Bar & Table Top Epoxy: Part A and B", are resinous polymeric coatings. These resinous polymeric coatings have been tested by an independent Testing, Inspection and Certification laboratory for conformity to Food and Drug Administration (FDA) standards as required by 21 CFR 175.300 Condition E from Table 2. Epoxy prepared pursuant to product instructions passed the FDA Standard extraction testing under standard conditions of use. The products were found to be in compliance with the US Food and Drug Administration regulation, 21 CFR 175.300, Condition E, for surfaces in contact with food at room temperature. Other conditions of use or variations in preparation or application of the resin would potentially require follow up testing.

The above statement refers to “clear” epoxy only. Adding any type of colorant to either epoxy alters the epoxy formula and it will no longer conform to the USFDA 21 CFR 175.300 tested results.

You may email info@wisebond.com for additional information and testing.

NOTE: WiseBond® Epoxies are 100% solids and VOC-Free. Once epoxy is mixed properly according to the instructions and fully cured for 30 days, it is an inert plastic. It is not antimicrobial. Epoxy is not safe to ingest (liquid or cured). Do not cut on or prepare raw food on epoxy surfaces.

Epoxy can and will melt when exposed to a flame and can catch fire. Always keep away from heat and open flames. When exposed to higher temperatures, a maximum of 120F (50C) should be adhered to at all times.

© 2025 - WiseBond®, A product of DeckWise®, The Ipe Clip® Fastener Company