Due to DOT regulations, epoxy MUST ship ground. Expedited shipping is not possible.

Imagine the beautiful epoxy jewelry rings and pendants to gorgeous wood epoxy teardrop and heart-shaped necklaces. Just think of the holiday gift ideas for family and friends with hand-made pieces of art, charm bracelets, pressed flowers, or inspirational gifts of love encased in epoxy!

Imagine the beautiful epoxy jewelry rings and pendants to gorgeous wood epoxy teardrop and heart-shaped necklaces. Just think of the holiday gift ideas for family and friends with hand-made pieces of art, charm bracelets, pressed flowers, or inspirational gifts of love encased in epoxy!

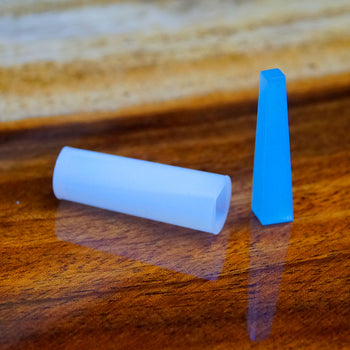

Just combine any amount at the 1:1 ratio, mix thoroughly, and pour! This epoxy is self-levelling for coating flat and smooth surfaces. Use it for casting objects and making 3-dimensional artwork. Beverage tumblers effortlessly coated to enhance and protect the beauty of underlying artwork and smoothly releases from silicone molds for multiple castings.

100% solids and VOC-Free. No fumes. No solvents. Non-flammable. Low odor. Safe for indoor use.

Add colorants, dyes, or powders to add gorgeous effects to your one-of-a-kind epoxy artwork or drink cup. This epoxy is glossy, shiny, durable and increases the allure of anything it’s applied to!

Art & Tumbler Epoxy is formulated to offer the most clarity possible with UV inhibitors.

Always use proper PPE. Pour equal amounts (1:1 ratio by volume) of A and B into a mixing cup. Mix more than you need to ensure to completely cover your work and not come up short

Stir SLOWLY! Mixing too fast will introduce air bubbles. Stir for at least 3 minutes while scraping the cup sides and bottom. Unmixed A or B material will not cure. Pour mixture into a fresh clean cup and mix 1 more minute to ensure a well-mixed product.

Once you mix the A and B together, you’ll have about 15-20 minutes of pot life time before the resin thickens and cures in the mixing cup. CAUTION! Only mix as much as needed in small batches. Unused epoxy can and will begin to heat up within 10-20 minutes - depending on volume - when left in mixing containers. Do not allow extra unused epoxy to sit! Pour all unused epoxy onto a scrap piece of wood or piece of cardboard in a thin layer to prevent overheating.Be sure the project it is level, free of dust/dirt and the room temp is around 72 degrees. The epoxy will self-level and this is when you can spread it, move it or manipulate it. Any bubbles are easily popped with a heat gun.

Once you begin using (pouring or spreading) the mixed epoxy, you’ll have about 30-45 minutes of working time before the resin thickens and begins cures.Epoxy needs to cure for 24 hours for its initial cure. Within 8-12 hours it will have a hard tack. This is when you can pour a second layer if so desired. In about 12-18 hours, it will be dry to the touch and can be moved without damage. Do not remove from molds yet. At 24 hours is when it can be handled or removed from a mold. A full cure is in 72 hours and 30 days it will be a full-hard cure.

FOOD SAFETY: Products "WiseBond® Deep Pour 2” Epoxy: Part A and B, and WiseBond® Bar & Table Top Epoxy: Part A and B", are resinous polymeric coatings. These resinous polymeric coatings have been tested by an independent Testing, Inspection and Certification laboratory for conformity to Food and Drug Administration (FDA) standards as required by 21 CFR 175.300 Condition E from Table 2. Epoxy prepared pursuant to product instructions passed the FDA Standard extraction testing under standard conditions of use. The products were found to be in compliance with the US Food and Drug Administration regulation, 21 CFR 175.300, Condition E, for surfaces in contact with food at room temperature. Other conditions of use or variations in preparation or application of the resin would potentially require follow up testing.

The above statement refers to “clear” epoxy only. Adding any type of colorant to either epoxy alters the epoxy formula and it will no longer conform to the USFDA 21 CFR 175.300 tested results.

You may email info@wisebond.com for additional information and testing.

NOTE: WiseBond® Epoxies are 100% solids and VOC-Free. Once epoxy is mixed properly according to the instructions and fully cured for 30 days, it is an inert plastic. It is not antimicrobial. Epoxy is not safe to ingest (liquid or cured). Do not cut on or prepare raw food on epoxy surfaces.

Epoxy can and will melt when exposed to a flame and can catch fire. Always keep away from heat and open flames. When exposed to higher temperatures, a maximum of 120F (50C) should be adhered to at all times.

© 2026 - WiseBond®, A product of DeckWise®, The Ipe Clip® Fastener Company