WiseBond® Deep Pour Epoxy is a premium commercial grade epoxy specially formulated for river table thick pouring up to 2 in. deep in a single pour and up to 8 in. thick for object castings.

Due to DOT regulations, epoxy MUST ship ground. Expedited shipping is not possible.

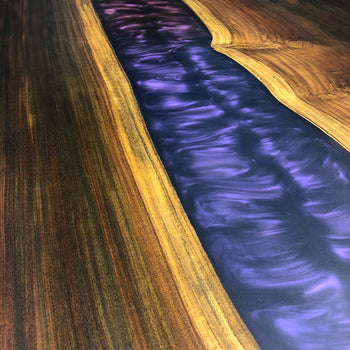

Perfect for live-edge river tables, creative table making, wood slabs, wood working, and object art casting projects. This epoxy is cures to a crystal clear water-like appearance and designed for a long cure to make it easy to work with.

Perfect for live-edge river tables, creative table making, wood slabs, wood working, and object art casting projects. This epoxy is cures to a crystal clear water-like appearance and designed for a long cure to make it easy to work with.

WiseBond® Deep Pour Epoxy has been engineered to be low-odor, and zero VOC with a slow exothermic reaction to prevent cracking and shrinkage. Powdered colorants, dyes, and alcohol inks can be mixed into the epoxy for amazing special effects adding vibrancy to any river table, encapsulated object, voids, turning projects, custom wood tables or art projects.

Our Deep Pour epoxy can be colored/tinted with WiseColor™ mica powder, alcohol inks, opaque resin pigments, or our color shift/glow-in-the-dark/fluorescent resin tints!

WiseBond® Deep Pour epoxy features a 2:1 mixing ratio and can be used indoors without ventilation or bulky respiration equipment. Each epoxy kit includes a resin (part A) and a hardener (part B).

Pour at temperatures between 77°F- 85°F with low humidity in a dust free environment. Allow 12-24 hours between pouring additional layers. Wait 3 days for a full cure and 30 days for a full hard cure.

WiseBond® Deep Pour epoxy poured with live-edge wood slabs, preserves the wood, brings out the natural wood luster, and highlights the natural wood grains. America's choice for self-leveling, water and chemical resistance, the strongest Deep Pour Epoxy on the market!

WiseBond® Deep Pour Epoxy is a Low heat, Low VOC, and Low odor making this product perfect for both the professional artist and the everyday woodworking hobbyist.

This product is NOT to be poured or used less than 1/2" in thickness.

For a 1/8" glossy, self-leveling finish coat use WiseBond® Bar & Table Top Epoxy.

When WiseBond® Deep Pour Epoxy is used in small amounts, the drying time will slow but it will still cure. WiseBond® Deep Pour casting resin is not designed as the final coat. This product is NOT to be used for normal 1/8" flood coat pour.

FOOD SAFETY: Products "WiseBond® Deep Pour 2” Epoxy: Part A and B, and WiseBond® Bar & Table Top Epoxy: Part A and B", are resinous polymeric coatings. These resinous polymeric coatings have been tested by an independent Testing, Inspection and Certification laboratory for conformity to Food and Drug Administration (FDA) standards as required by 21 CFR 175.300 Condition E from Table 2. Epoxy prepared pursuant to product instructions passed the FDA Standard extraction testing under standard conditions of use. The products were found to be in compliance with the US Food and Drug Administration regulation, 21 CFR 175.300, Condition E, for surfaces in contact with food at room temperature. Other conditions of use or variations in preparation or application of the resin would potentially require follow up testing.

The above statement refers to “clear” epoxy only. Adding any type of colorant to either epoxy alters the epoxy formula and it will no longer conform to the USFDA 21 CFR 175.300 tested results.

You may email info@wisebond.com for additional information and testing.

NOTE: WiseBond® Epoxies are 100% solids and VOC-Free. Once epoxy is mixed properly according to the instructions and fully cured for 30 days, it is an inert plastic. It is not antimicrobial. Epoxy is not safe to ingest (liquid or cured). Do not cut on or prepare raw food on epoxy surfaces.

Epoxy can and will melt when exposed to a flame and can catch fire. Always keep away from heat and open flames. When exposed to higher temperatures, a maximum of 120F (50C) should be adhered to at all times.

© 2026 - WiseBond®, A product of DeckWise®, The Ipe Clip® Fastener Company